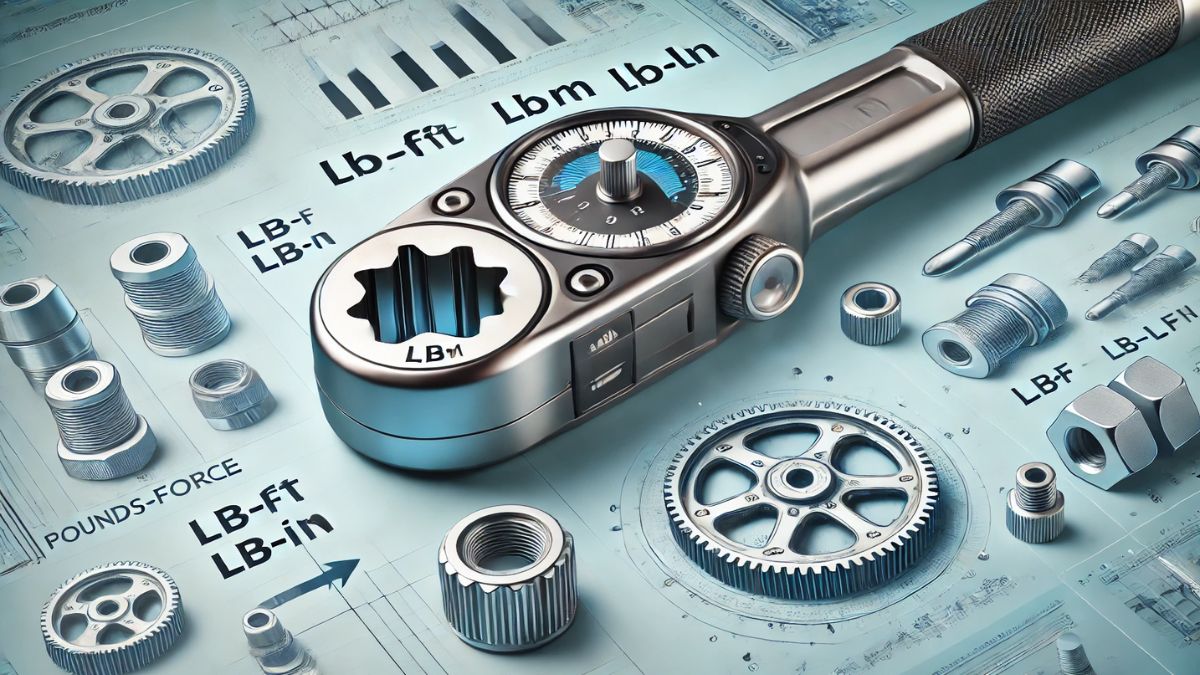

Torque wrenches are essential tools for professionals and DIY enthusiasts alike, ensuring that bolts and fasteners are tightened to the correct tension. However, when it comes to selecting and using the right torque wrench, you’ll often come across units like lb, lbm, and lbf. Understanding what these terms mean is crucial to ensure proper usage and accurate torque measurements. This guide will break down the key differences and applications of these terms, helping you make informed decisions about your torque wrench.

What is a Torque Wrench?

Before we dive into the technical terms, let’s first understand what a torque wrench is. A torque wrench is a precision tool used to apply a specific torque to a fastener, such as a bolt or nut. Torque wrenches are vital in automotive work, machinery repair, and even bicycle maintenance, where precise tightness is required to avoid damage or failure. They help you achieve consistent and accurate tightening, preventing over-tightening or under-tightening, which can cause significant issues in mechanical systems.

Defining the Key Terms: lb, lbm, and lbf

When dealing with torque wrenches, you’ll often encounter three key terms: lb, lbm, and lbf. Each term refers to different units of measurement, and understanding them is important for choosing the correct tool and making accurate torque calculations.

1. What Does “lb” Mean?

In the context of torque wrenches, “lb” refers to pounds, a unit of mass or weight commonly used in the United States and other countries that follow the Imperial system. It is a basic unit that is often used as shorthand for other torque measurements.

In the case of torque wrenches, however, “lb” alone doesn’t tell you everything you need to know. It’s usually paired with either “ft” or “in” (as in lb-ft or lb-in), which refers to pounds-force applied per foot or inch. We’ll break these down in a bit.

2. What is “lbm” (Pound-Mass)?

The term “lbm” stands for pound-mass. It is used to express mass in the Imperial system, which is essentially a measure of how much matter is in an object. Pound-mass (lbm) is not typically used when describing torque but rather when dealing with the object’s mass or weight. While it’s not directly related to torque wrench settings, understanding lbm is still important when calculating the mass or weight of components being tightened.

Here’s a quick way to differentiate:

- lb refers to the general measurement of weight (without detail).

- lbm specifies the mass of the object.

3. What is “lbf” (Pounds-Force)?

Pounds-force (lbf) is where torque measurements come into play. Torque is a measure of rotational force, and lbf refers to the amount of force applied. In most torque wrench settings, you’ll see torque measured in lb-ft (pounds-force feet) or lb-in (pounds-force inch). These terms indicate the force applied over a certain distance—either feet or inches—from the pivot point.

For example:

- lbf-ft (Pound-Force Feet): This is one pound-force applied over a one-foot distance. It’s a standard unit used for torque measurements in automotive, machinery, and larger systems.

- lbf-in (Pound-Force Inch): This is one pound-force applied over a one-inch distance. This is often used for smaller precision applications, such as bicycle maintenance or small machinery.

Importance of Understanding lb, lbm, and lbf in Torque Wrenches

Understanding the differences between lb, lbm, and lbf is essential for a few key reasons:

1. Precision in Work

When working with fasteners, ensuring that the torque is applied correctly is vital. Too much torque (over-tightening) can damage the fastener, while too little torque (under-tightening) can cause failure. Knowing the exact force you’re applying—measured in lbf—ensures that you’re using the right amount of torque for the job.

2. Avoiding Costly Mistakes

Without understanding the difference between these units, you might select the wrong torque wrench or apply the wrong settings, leading to mechanical issues or even equipment failure. A precise torque wrench set to lb-ft or lb-in ensures you achieve the perfect balance between tightness and durability.

3. Ensuring Safety

In many industries—especially automotive and construction—safety is paramount. Incorrect torque can lead to catastrophic mechanical failures. Understanding these units ensures you’re tightening bolts and fasteners to the manufacturer’s specifications, preventing potential hazards.

Key Points to Remember When Using a Torque Wrench

Now that we’ve covered the basics, here are some essential points to keep in mind when using a torque wrench:

1. Select the Right Unit

Always check the manufacturer’s specifications for the correct torque unit. For most automotive applications, this will be measured in lb-ft. For smaller, more precise applications, lb-in may be specified. Using the wrong unit can lead to inaccurate torque applications.

2. Calibrate Your Torque Wrench

Torque wrenches need to be calibrated regularly to ensure accuracy. Over time, the internal mechanisms can wear out, leading to inaccurate readings. Make sure to follow the manufacturer’s recommendations for recalibration.

3. Use the Right Adapter

If you’re working with a torque wrench that requires an adapter (for instance, switching from lb-ft to lb-in), ensure the adapter is suitable for the torque range you’re working in. Incorrect adapters can lead to inaccurate torque application and damage to both the fastener and the tool.

4. Apply Torque Slowly and Evenly

When applying torque, always do so slowly and evenly to avoid over-tightening. A fast, jerky motion can result in applying too much torque, which could lead to fastener damage. Slow, consistent pressure allows for better control.

5. Store Your Torque Wrench Properly

Torque wrenches are sensitive instruments that need to be stored properly to maintain their accuracy. When not in use, store your wrench in a clean, dry environment and release the tension by setting it to its lowest setting (but not zero).

How to Choose the Right Torque Wrench for Your Needs

Choosing the right torque wrench depends on the application you’re working on. Here are a few tips to help you make the right choice:

1. Identify Your Application

Are you working on a car, motorcycle, bicycle, or heavy machinery? Each type of job will have different torque requirements. Automotive work typically requires lb-ft measurements, while smaller tasks, like working on bicycles or electronics, will often use lb-in.

2. Check Torque Ranges

Different torque wrenches come with varying torque ranges. A typical range might be between 10 to 150 lb-ft for automotive applications, while more precision-based work might require lower ranges like 5 to 50 lb-in. Ensure the wrench you choose covers the range you need.

3. Consider a Digital Torque Wrench

For those who want the utmost precision, a digital torque wrench can be an excellent choice. These wrenches provide digital readouts and alerts, giving you better control over the torque you’re applying.

4. Look for Durability

Ensure the wrench you choose is made of high-quality materials like chrome-vanadium steel, which offers better durability and longevity. Investing in a good quality wrench will save you money in the long run by ensuring it can withstand frequent use without losing accuracy.

Conclusion

Understanding the differences between lb, lbm, and lbf is crucial when working with torque wrenches. These terms directly influence how much force you’re applying and ensuring that force is applied accurately is critical to both the safety and functionality of any mechanical system. Whether you’re a professional mechanic or a DIY enthusiast, using the correct torque settings will help you achieve optimal results while protecting your tools, fasteners, and projects. Keep these guidelines in mind, and you’ll be well-equipped to choose and use the right torque wrench for any job.